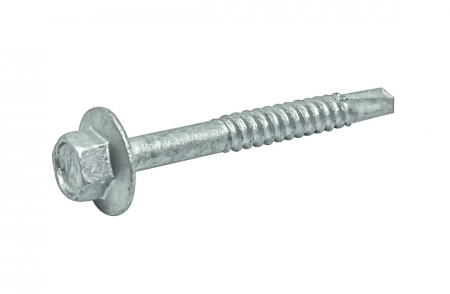

Mechanical Zinc Screw

H03

Mechanical Galvanized Screw

Mechanical galvanized screws work in high corrosion environment. It can be compliant with ASTM B117, ASTM B695, DIN50018, DIN50021 and AS3566.2.

Compliant Salt Spray test hours can be 96 hours, 192 hours, 220 hoursm 250 hours, 1000 hours, 1500 hours and 2000 hours.

15 cycles and 20 cycles of Kesternich test are available.

Mechanical galvanization allows screws to comply with various corrosion test protocols by providing a zinc coating. The screws can resist salt spray and Kesternich testing for extended periods, demonstrating their effectiveness for high corrosion environments. Compliance with standards like ASTM B117 validates their anti-corrosion capabilities.

Landwide Screw DNA

Contact our sales team now via sales@landwide.com.tw and send your question or drawing for assistance.

- Gallery

- FAQ

What types of screws do you manufacture?

We manufacture a wide range of screws, including self-drilling screws, drywall screws, decking screws, self-tapping screws, roofing screws, stainless steel...

How Can We Ensure Fastener Integrity in Saltwater Environments for 15+ Year Service Life?

Our mechanical galvanized screws with up to 2000 hours salt spray test certification provide proven long-term corrosion protection for offshore platforms, marine structures, and coastal installations. With full ASTM B117 and ASTM B695 compliance, we eliminate premature fastener failure that leads to costly maintenance and safety risks. Contact our technical team to review your project specifications and receive customized recommendations for optimal corrosion resistance in your specific marine application.

Beyond standard salt spray resistance, our screws successfully pass rigorous Kesternich testing protocols with 15 and 20-cycle certifications, demonstrating superior performance against sulfur dioxide exposure and acidic atmospheric conditions. Backed by 29 years of fastener manufacturing expertise and quality-monitored production processes, Landwide provides not just premium screws but comprehensive technical consultation to ensure you select the optimal corrosion protection level for your application. Our experienced sales and engineering teams are ready to answer your technical questions, review your drawings, and recommend customized solutions that meet your exact specifications. Contact our team at sales@landwide.com.tw to discuss how our mechanical zinc screws can extend the service life of your installations while reducing long-term maintenance costs.